Our flagship malt distillery in Indri, Haryana spans 168 acres and produces SIngle Malt Whisky, Cask Aged Rum, Extra Neutral Alcohol (ENA), and Ethanol, with a capacity of 220 KLPD ENA and 30 KLPD malt spirit. Sustainability is core to our operations, using biomass energy and non-GMO six-row barley for spirits with a distinctive sweet, fruity profile. Our warehouses mature over 75,000 barrels in diverse casks, from Virgin American Oak to PX Sherry.

Expanding further, we are establishing a state-of-the-art facility in Mahasamund, Chhattisgarh with a production capacity of 180 KLPD of Extra Neutral Alcohol (ENA) and 30 KLPD dedicated to malt production.

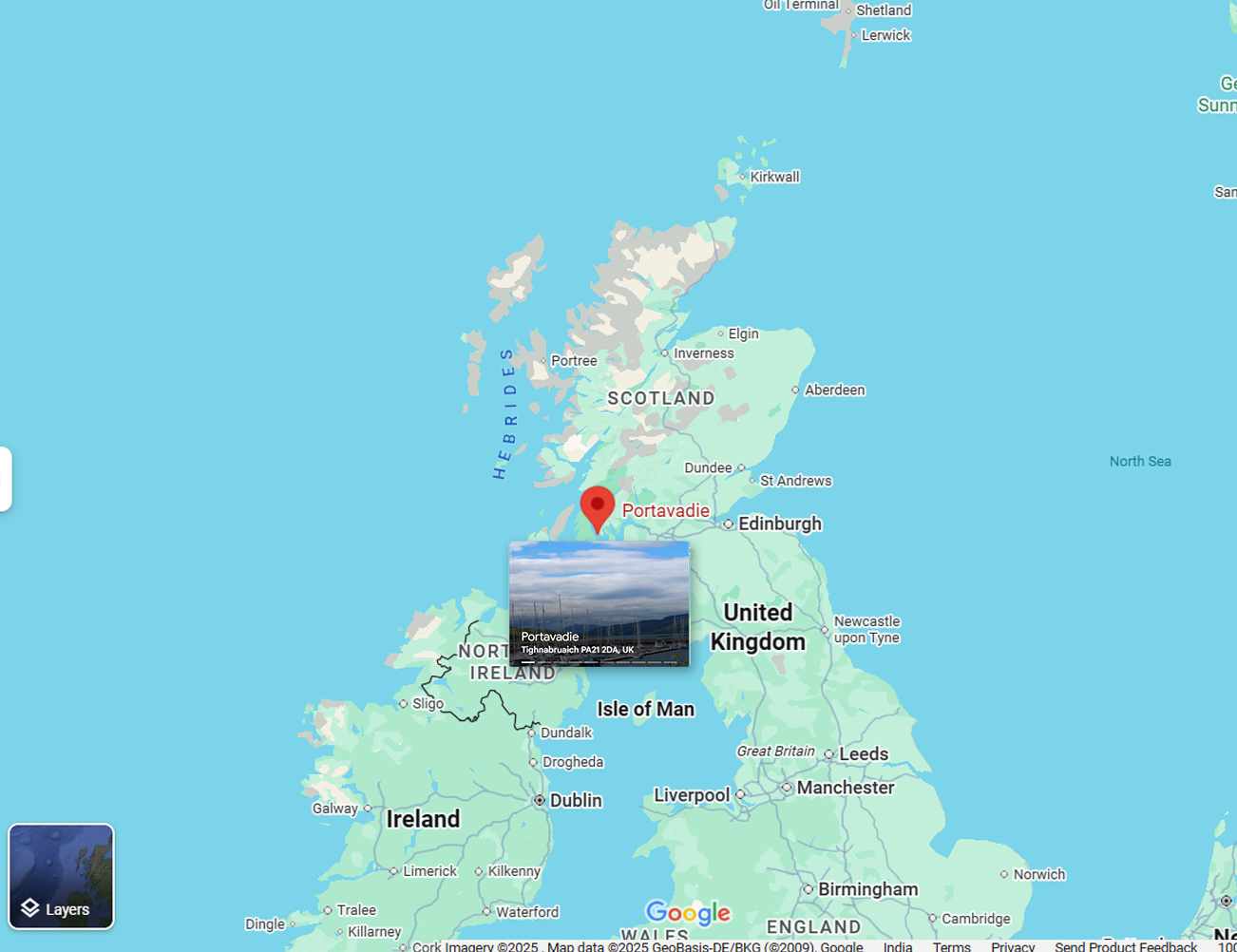

Marking an industry first for an Indian alco-bev company, Piccadily is establishing an international malt distillery in Portavadie, Scotland. With HMRC approvals in place, this site will produce premium Scotch-style malts and feature a world-class visitor centre, positioning Piccadily as a global leader in whisky.